Ever wonder how your online order arrives so fast or why stores rarely run out of stock? The answer lies in the warehouse: the core of modern logistics.

Warehousing has evolved from simple storage to a key part of how products move, orders ship, and customers stay satisfied. When a warehouse runs efficiently, deliveries are faster, cheaper, and more reliable.

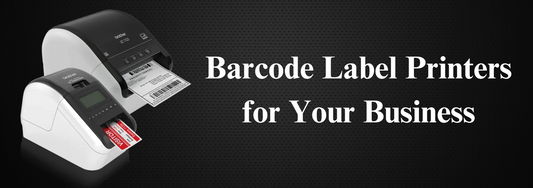

A big reason behind this progress is barcode technology. Those black-and-white lines on every product let scanners capture data instantly, replacing slow manual entry with real-time accuracy. Every scan helps track items from shelf to shipment with precision.

As consumers demand faster delivery and flawless service, warehouses must handle more products, tighter deadlines, and higher expectations. Barcode systems make that possible—bringing speed, accuracy, and control to every step of the supply chain.

Limitations of Traditional Warehouse Management

Many warehouses still rely on manual operations, where staff record and input data by hand. This outdated approach is slow, error-prone, and inefficient. Paper-based documentation and manual tracking lead to:

-

Frequent errors and delays: Data quickly becomes outdated, and tracking accuracy suffers.

-

Disorganized inventory: Products are misplaced, and space is poorly used.

-

High operational costs: Manual work increases labor time and overhead costs.

Common Problems in Manual Systems

| Problem | Impact |

|---|---|

| Manual data entry | High error rate (1 in 300) |

| Paper documentation | Slow information flow |

| Random storage | Space waste and confusion |

| Human dependency | Increased risk and cost |

Traditional management methods can no longer meet the efficiency and accuracy demands of modern supply chains. A smarter, automated approach is required.

Advantages of Barcode Warehouse Management Systems (WMS)

A barcode-enabled Warehouse Management System (WMS) integrates key warehouse functions: receiving, storage, inventory control, picking, and shipping into one seamless platform. The results are higher accuracy, faster operations, and lower costs.

High Reliability and Speed:

Barcode scanning achieves accuracy rates up to 99.9999%, compared to 99.7% for manual entry. Scanning is five times faster, significantly improving throughput.

Reduced Costs and Risks:

Automation simplifies data entry, minimizes errors, and reduces training time. Fewer mistakes mean lower operating costs and fewer returns.

Real-Time Visibility:

Barcode systems update inventory data instantly, allowing managers to monitor stock levels and product movement in real time.

Scalability:

Barcode-based WMS platforms are modular and easily integrate with ERP or other enterprise systems, supporting business growth and expansion.

Real Applications of Barcode Systems in Warehouses

Goods Receiving (Inbound)

When products arrive, workers scan barcoded labels to record quantities and supplier details. The data is instantly uploaded to the WMS.

Benefits: Faster receiving, fewer errors, and paperless record-keeping.

Goods Dispatching (Outbound)

Orders are sent to handheld scanners. Staff pick and scan products to verify accuracy before shipping.

Benefits: Faster order fulfillment, instant feedback, and complete traceability.

Inventory Counting

Scanning barcodes during stocktaking compares real-time counts with system data.

Benefits: Instant variance reports, accurate reconciliation, and reduced labor costs.

Inventory Relocation

When moving products between storage areas, workers scan both the item and the new location barcode.

Benefits: Real-time tracking, better space use, and higher efficiency.

A barcode-based WMS typically includes:

-

Data transmission: Real-time communication between handheld scanners and the central database.

-

Data synchronization: Automated upload and download for verification and updates.

-

Duplicate prevention: The system identifies and blocks duplicate entries.

-

Document control: Unique order numbers prevent mix-ups between customers or batches.

Cost-Effective Solutions for Small and Medium Enterprises

Small and medium-sized enterprises (SMEs) can implement barcode management systems cost-effectively by combining:

-

Handheld scanning devices for data capture

-

PC-based software for warehouse control

-

Barcode printers for label generation

Advantages:

Low cost, easy setup, flexible operation, and scalability. Such systems are ideal for industries like retail, manufacturing, and healthcare that require efficient inventory management.

Case Studies: Barcode Systems in Action

Automated Central Warehouse

A 3,200 m² distribution center implemented barcode-controlled conveyors and automated guided vehicles (AGVs). Fixed scanners identified pallets and directed their movement with precision, resulting in faster processing and higher accuracy.

Mitsubishi Heavy Industries

By adopting a barcode-driven WMS, Mitsubishi achieved 100% inventory accuracy, zero stock discrepancies, and shorter operational times: without hiring additional staff.

Read more Case studies to find your solution here

The Future of Barcode Warehouse Management

Integrating barcode technology into warehouse operations transforms manual processes into smart, automated systems. It enhances speed, precision, and visibility while reducing human error and cost.

Barcode-driven warehouse management doesn’t just improve efficiency—it builds a foundation for digital transformation across the entire supply chain. As logistics continues to evolve, barcode technology remains a cornerstone of warehouse automation, delivering the speed, accuracy, and transparency that modern commerce demands.